Material: Stainless Steel 304/316

Type: Hook & Eye, Hook & Hook, Eye & Eye

Process: Forging

Size: 4mm-48mm

Packing: Cartons or Gunny Bags and then on Pallets.

Material: Stainless Steel 304/316

Type: Hook & Eye, Hook & Hook, Eye & Eye

Process: Forging

Size: 4mm-48mm

Packing: Cartons or Gunny Bags and then on Pallets.

STAINLESS STEEL TURNBUCKLE

A stainless steel turnbuckle is a type of hardware used to adjust the tension or length of ropes, cables, or wires. It consists of two end fittings (often eye bolts or hooks) connected by a threaded body that can be adjusted by rotating it. The threaded body allows for easy tightening or loosening of the turnbuckle, allowing for fine adjustments to the tension in the connected components.

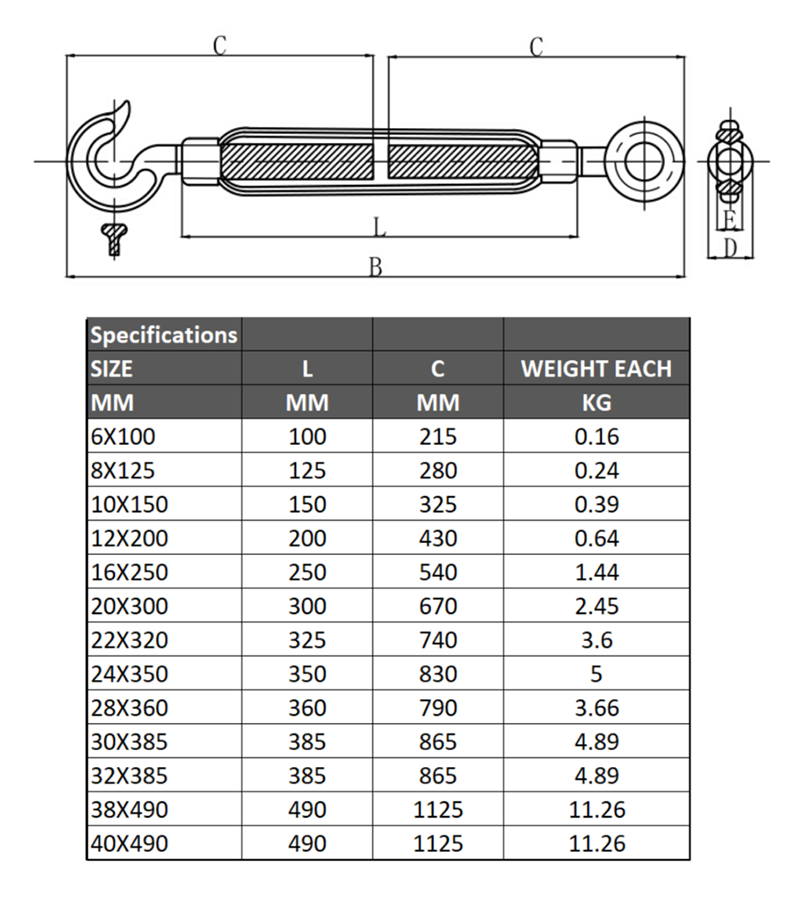

DIMENSIONS

END TYPES OF STAINLESS STEEL TURNBUCKLE

Turnbuckles can have different end types or end fittings to suit various applications and connection requirements. The end types typically include the following:

1. Hook Ends: Turnbuckles with hook ends have a hook-shaped fitting on each end. These hooks can be use to attach the turnbuckle to an anchor point or other components in the system.

2. Eye Ends: Turnbuckles with eye ends have an eyelet or loop-shaped fitting on each end. These eye ends allow for easy connection of the turnbuckle to other components using pins, bolts, or other fasteners.

3. Hook and Eye Ends: Some turnbuckles may have a combination of a hook end on one side and an eye end on the other side. This provides flexibility in connecting the turnbuckle to different types of components.

4. Threaded Rod Ends: Turnbuckles with threaded rod ends have a threaded rod on each end. These rods can be directly screw into or connected with other threaded components.

5. Jaw Ends: Turnbuckles with jaw ends have a jaw-shaped fitting on each end. The jaws can be use to secure the turnbuckle to other components or attachments.

6. Jaw and Eye Ends: Turnbuckles with jaw and eye ends have a jaw and eye fitting on each end. The jaw can accommodate pins, bolts, or other fasteners to connect with other components.

ADVANTAGES OF STAINLESS STEEL TURNBUCKLE

The primary advantage of using stainless steel for turnbuckles is its corrosion resistance, making it suitable for outdoor and marine applications where exposure to moisture and harsh environments is a concern. Stainless steel is also preferred in situations where the turnbuckles need to maintain their appearance or structural integrity over time.

Common Uses of Turnbuckles

Stainless steel turnbuckles find various applications in industries such as construction, marine, rigging, and other heavy-duty applications where secure tensioning of cables and wires is essential.

Professional Turnbuckle Supplier in China

Kailipu is a professional turnbuckle supplier and manufacturer in China. We supply hundreds of high-quality turnbuckles. For any more help, e-mail our specialists at sales@qd-kailipu.com for assistance.