Technical Notes:U.S. Federal Specification(ASME B30.26)

Material: Body-Super Carbon Steel. Screw Pin-Alloy Steel

Safety Factor: 6 : 1 / 4 : 1

Processing: Body-Drop Forged / Quenched and Tempered

Screw Pin-hot/cold forging / Drop Forged / Quenched and Tempered

Finish: Body-Hot Dipped Galvanized / Powder Coated / Zinc Plated

Screw Pin-Powder Coated / Zinc Plated

Size: From 3/16”to 2-1/2”

Packing: Cartons or Gunny Bags and then on Pallets.

Technical Notes:U.S. Federal Specification(ASME B30.26)

Material: Body-Super Carbon Steel. Screw Pin-Alloy Steel

Safety Factor: 6 : 1 / 4 : 1

Processing: Body-Drop Forged / Quenched and Tempered

Screw Pin-hot/cold forging / Drop Forged / Quenched and Tempered

Finish: Body-Hot Dipped Galvanized / Powder Coated / Zinc Plated

Screw Pin-Powder Coated / Zinc Plated

Size: From 3/16”to 2-1/2”

Packing: Cartons or Gunny Bags and then on Pallets.

G209 SHACKLE US TYPE SCREW PIN ANCHOR

A g209 shackle also known as Crosby G-209 Forged Screw Pin Anchor Shackle. It is a type of lifting and rigging hardware use to secure and connect various components in heavy-duty lifting and rigging operations. The degsin can provide a strong and reliable connection point between different elements, such as chains, slings, wire ropes, or other lifting devices.

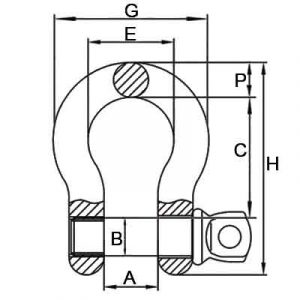

DIMENSIONS OF G209 SHACKLE:

| Size | Working | Weight | Dimensions (in.) | Tolerance +/- | |||||||

| Load | |||||||||||

| Limited | |||||||||||

| (in.) | (t) | (lbs) | A | B | C | E | G | H | P | C | A |

| 3/16 | 1/3 | 0.06 | 0.38 | 0.25 | 0.88 | 0.6 | 0.98 | 1.47 | 0.19 | 0.06 | 0.06 |

| 1/4 | 1/2 | 0.1 | 0.47 | 0.31 | 1.13 | 0.78 | 1.28 | 1.84 | 0.25 | 0.06 | 0.06 |

| 5/16 | 3/4 | 0.19 | 0.53 | 0.38 | 1.22 | 0.84 | 1.47 | 2.09 | 0.31 | 0.06 | 0.06 |

| 3/8 | 1 | 0.31 | 0.66 | 0.44 | 1.44 | 1.03 | 1.78 | 2.49 | 0.38 | 0.13 | 0.06 |

| 7/16 | 1-1/2 | 0.38 | 0.75 | 0.5 | 1.69 | 1.16 | 2.03 | 2.91 | 0.44 | 0.13 | 0.06 |

| 1/2 | 2 | 0.72 | 0.81 | 0.63 | 1.88 | 1.31 | 2.31 | 3.28 | 0.5 | 0.13 | 0.06 |

| 5/8 | 3-1/4 | 1.37 | 1.06 | 0.75 | 2.38 | 1.69 | 2.94 | 4.19 | 0.69 | 0.13 | 0.06 |

| 3/4 | 4-3/4 | 2.35 | 1.25 | 0.88 | 2.81 | 2 | 3.5 | 4.97 | 0.81 | 0.25 | 0.06 |

| 7/8 | 6-1/2 | 3.62 | 1.44 | 1 | 3.31 | 2.28 | 4.03 | 5.83 | 0.97 | 0.25 | 0.06 |

| 1 | 8-1/2 | 5.03 | 1.69 | 1.13 | 3.75 | 2.69 | 4.69 | 6.56 | 1.06 | 0.25 | 0.06 |

| 1-1/8 | 9-1/2 | 7.41 | 1.81 | 1.25 | 4.25 | 2.91 | 5.16 | 7.47 | 1.25 | 0.25 | 0.06 |

| 1/1/4 | 12 | 9.5 | 2.03 | 1.38 | 4.69 | 3.25 | 5.75 | 8.25 | 1.38 | 0.25 | 0.06 |

| 1-3/8 | 13-1/2 | 13.53 | 2.25 | 1.5 | 5.25 | 3.63 | 6.38 | 9.16 | 1.5 | 0.25 | 0.13 |

NOTE:

When using a g209 bow shackle, it’s important to ensure that it is properly rated for the intended load and that it is securely closed and tightened. Proper inspection and maintenance of shackles are crucial to ensure their safe and effective use.

g209 shackles red pin

PRODUCT DESCRIPTION

Hello!Welcome to visit our website, hope our products can make you satisfied.

The g209 shackle you are looking at is also known as screw pin anchor shackle. It is a type of connecting link used in rigging and lifting applications. They are typically made from high-strength materials such as steel or stainless steel to withstand heavy loads and provide durability. It is an ‘O’ shaped metal link closed with a bolt, which is the most common type of rigging shackles.

Besides, this g209 shackle are available in various sizes and weight capacities, allowing them to be used for different loads and applications. It can provide a strong and secure connection point between lifting or rigging equipment, such as chains, ropes, or slings. It is commonly used in industries such as construction, maritime, and off-road vehicle recovery.

SURFACE TREATMENT OF THE SHACKLE

Shackles can undergo various surface treatments to enhance their durability, corrosion resistance, and overall performance. Some common surface treatments for shackles include:

1. Galvanizing: Galvanizing is a process in which the shackle is coated with a layer of zinc. The zinc coating provides a sacrificial barrier, meaning that if the shackle gets scratched or damaged, the zinc will corrode before the underlying steel, providing protection against rust and corrosion.

2. Hot-dip Galvanizing: Hot-dip galvanizing is a specific method of galvanizing. It involves immersing the shackle in a bath of molten zinc at temperatures typically around 450 to 480 degrees Celsius. The high temperatures allow the zinc to form a metallurgical bond with the steel, creating a robust and durable coating. Hot-dip galvanizing provides excellent corrosion protection and is commonly used in applications where the shackle will be exposed to harsh environments. Such as marine or outdoor settings.

3. Powder Coating: Powder coating involves applying a dry powder to the surface of the shackle, which is then cured under heat to form a protective layer. Powder coating provides a durable and decorative finish, protecting the shackle from corrosion, chemicals, and abrasion.

4. Electropolishing: Electropolishing is an electrochemical process that removes surface imperfections and contaminants, resulting in a smooth and clean finish. This treatment improves the corrosion resistance of stainless steel shackles and enhances their appearance.

5. Paint Coating: Shackles can coat with various types of paint to provide protection against corrosion. Paint coatings are commonly used in applications where aesthetic appeal is important, as they can be applied in different colors.

g209 screw pin anchor shackle

Professional Shackle Supplier in China

Kailipu is one of the most professional shackle supplier in China, we supplies hundreds of high tensile lifting and rigging shackles. Among them, the G209, G210, G2130, G2150, European Large D, BK shackles are the most representative. Meanwhile, our specifications range from 0.33 tons to 500 tons, which covers almost all sizes you will need. If you are looking for a professional shackle supplier, do not hesitate to contact us at sales@qd-kailipu.com.